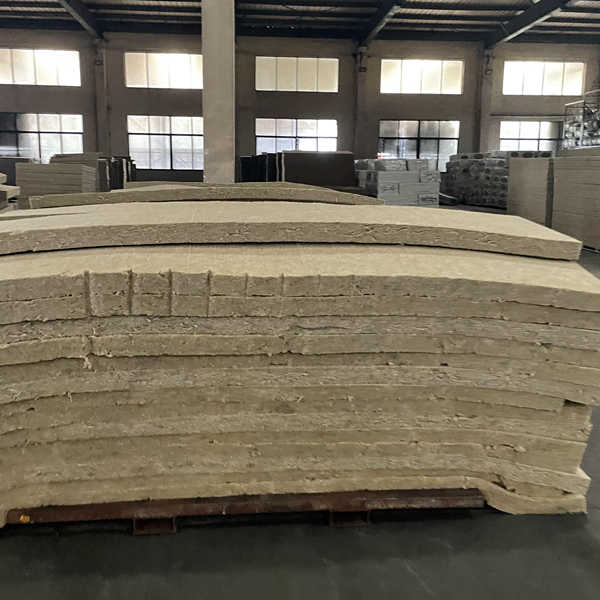

Width: 600mm

Length: 5m

Thickness: 50mm, 75mm, 100mm

Density: 50kg/m3, 60kg/m3, 80kg/m3

Facing: Plain wool

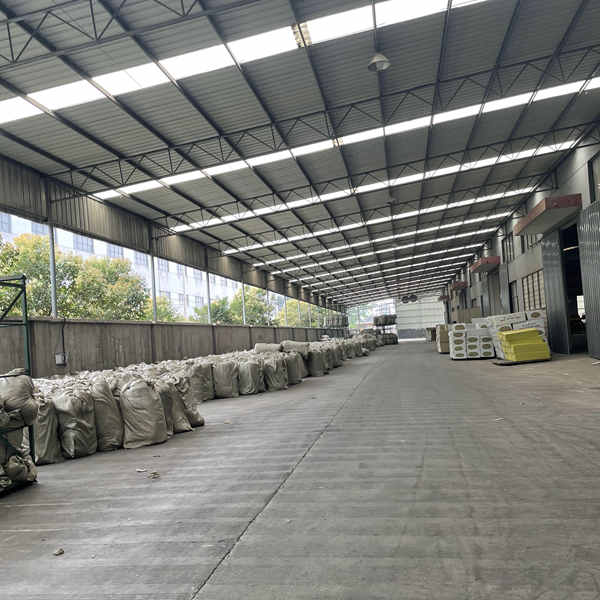

Package: ISOKING Standard Package

In the converter shop of a steel mill, converter vapor cooling pipes are like busy arteries, providing critical support for the production process, while rock wool rolls become the faithful "guardians" of these pipes to ensure their efficient operation.

Converter vaporization cooling pipes carry high-temperature, high-pressure vapor-water mixtures, and insulation is critical to maintaining the performance of the pipes and the stability of production. Rock wool rolls play a key role here with their excellent insulation properties.

Rock wool rolls consist of fine, high-quality rock wool fibers that are interwoven to form countless tiny insulation pores. When tightly packed around the converter's vaporization and cooling pipes, the rolls create a strong thermal barrier for the pipes.

During the flow of the high-temperature vapor-water mixture inside the pipe, the rock wool rolls effectively prevent the heat from escaping to the outside. This not only helps to maintain the temperature of the medium inside the pipe and safeguard the vapor cooling effect, but also reduces energy waste. Even in the case of low ambient temperatures, the heat inside the pipeline can be well preserved, so that the medium can flow smoothly in the pipeline, to maintain the stability of the converter production.

This excellent thermal insulation brings multiple benefits. For one thing, it improves the efficiency of energy utilization. By reducing heat loss, it reduces the energy consumption in the production process, saving a lot of cost for the enterprise. Two, it helps to extend the service life of pipes. A stable temperature environment reduces the stress on pipes due to thermal expansion and contraction, reducing the risk of pipe fatigue and damage.

In addition, rock wool rolls have good fireproofing and soundproofing properties. In the complex and high-temperature environment of steel mills, it can effectively reduce the risk of fire, and at the same time reduce the noise generated by the operation of the pipeline.

In practice, the installation of rock wool rolls is relatively easy, and can adapt to the complex direction and shape of the pipeline. Construction personnel can be cut and spliced according to the specific conditions of the pipeline, to ensure that the rock wool rolls and pipeline close fit, to achieve a full range of thermal insulation coverage.

In short, rock wool roll in the converter vaporization cooling pipe insulation plays an indispensable role. It provides a strong guarantee for the efficient, energy-saving and stable operation of iron and steel production, and is an important technical application in modernized iron and steel plants.