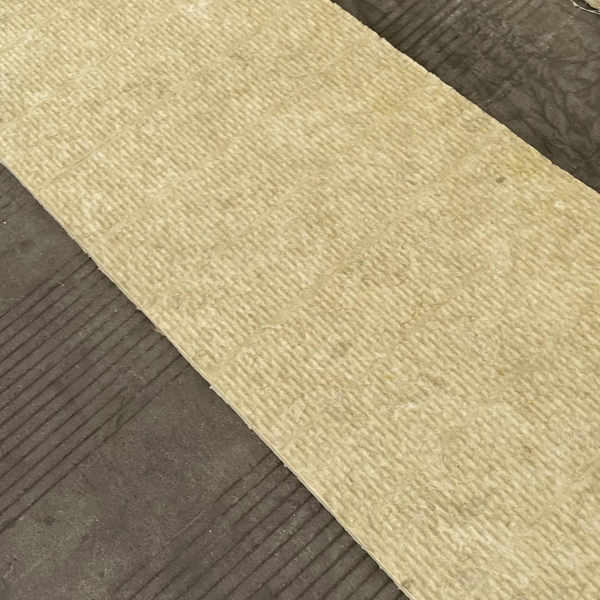

Rock Wool Insulation Roll

Width: 400mm, 600mm, 1000mm, 1200mm

Length: 2.5m, 3m, 5m

Thickness: 50mm, 100mm

Density: 50-130kg/m3

Package: ISOKING, OEM Available

In the huge system of the industrial field, steam pipes are like crisscrossing veins of energy, transporting vital heat energy to all corners. Rock wool rolls, as an excellent insulation material, play a key role in the insulation of steam pipes.

Steam flowing in steam pipes usually has a high temperature and pressure, in order to ensure that the steam in the transmission process to reduce heat loss, to maintain the efficient use of its energy, insulation measures are essential. Rock wool rolls are ideal for this purpose because of their unique properties.

Rock wool rolls consist of a fibrous material made from natural rock that has been melted at high temperatures. These fibers are fine and uniform, and are interwoven to form an intricate network structure. When tightly wrapped around the outer surface of a steam pipe, rock wool rolls act as a highly effective insulation suit for the pipe.

During the flow of steam, despite the high temperature inside the pipe, the rock wool rolls effectively block the heat from spreading outward. The rich fiber pores inside are filled with air, which has poor thermal conductivity, which greatly slows down the transfer of heat. At the same time, the rock wool fibers themselves have a low thermal conductivity, which further enhances the thermal insulation effect.

This excellent thermal insulation provides a number of significant benefits. First, it greatly reduces the heat loss of steam during transmission, improving energy utilization and reducing production costs. Secondly, it helps to maintain the temperature and pressure of steam at a stable level, which guarantees the normal operation of steam-driven equipment and the stability of the production process. Further, good heat insulation prevents the surface temperature of piping from becoming too high, reducing the risk of scalding personnel and improving safety in the workplace.

In addition, rock wool rolls have good fire, moisture and corrosion resistance. In the complex environment in which the steam pipeline is located, it can maintain stable thermal insulation for a long time, extending the service life of the pipeline.

In the actual construction process, rock wool rolls are easy to install and operate. It can be flexibly cut and spliced according to the shape and size of the pipeline to ensure a close fit with the pipeline, leaving no insulation dead space.

In summary, the application of rock wool rolls in steam pipe insulation not only provides reliable energy security for industrial production, but also plays an important role in energy saving, safety and stability, and is an indispensable part of modern industry.