Thickness: 50mm, 100mm

Density: 80kg/m3, 100kg/m3, 128kg/m3

Width: 0.6m, 1.2m...

Length: 1.2m, 2.4m...

Facing: No

Leadtime: Around 7-10 days after advance payment

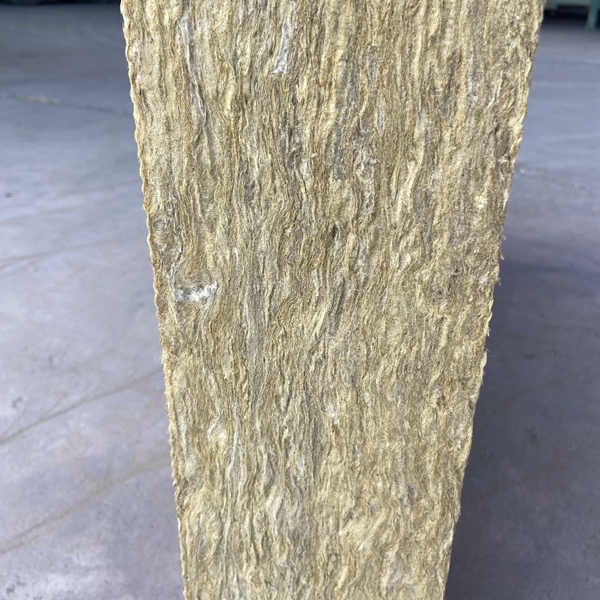

In the chemical industry, chemical storage tanks are vital equipment, and rock wool panels play an indispensable role in their insulation.

When used for chemical storage tank insulation, rock wool boards first show excellent thermal insulation performance. It can effectively reduce the tank material and the external environment of the heat exchange, whether you need to maintain a high temperature of the liquid or the need for low-temperature storage of chemicals, rock wool board can help maintain its ideal temperature state, which is of great significance to the stability of the chemical production process and product quality assurance.

Inevitably, there are some safety risks in the chemical field, and fire resistance is particularly critical. Rock wool panels have excellent fire protection properties, can be in the event of an accident, for the tank to provide a reliable fire barrier, to prevent the spread of fire, to protect the tanks and the surrounding facilities, to reduce the serious consequences of the fire may bring.

Chemical storage tanks in the environment is often more complex and variable, may be exposed to a variety of corrosive substances and different climatic conditions. Rock wool board has good corrosion resistance and durability, can withstand the impact of these unfavorable factors for a long time, always maintain its excellent thermal insulation performance and structural integrity.

The installation process is also relatively easy, and can be precisely adapted to the shape and size of the chemical tank to ensure a tight fit and form a continuous, effective insulation layer. Moreover, the construction of rock wool board will not cause too much interference to the normal use of chemical storage tanks.

At the same time, rock wool board also has a certain sound insulation effect, can reduce the storage tanks in the operation process may produce noise, for chemical enterprises to create a relatively quiet production environment.

In the long run, the choice of rock wool boards for chemical tank insulation can not only improve the efficiency and safety of chemical production, but also reduce energy consumption and operating costs. It provides strong support for the sustainable development of the chemical industry, ensures that chemical storage tanks can operate safely and efficiently, and contributes to the progress of the chemical industry.