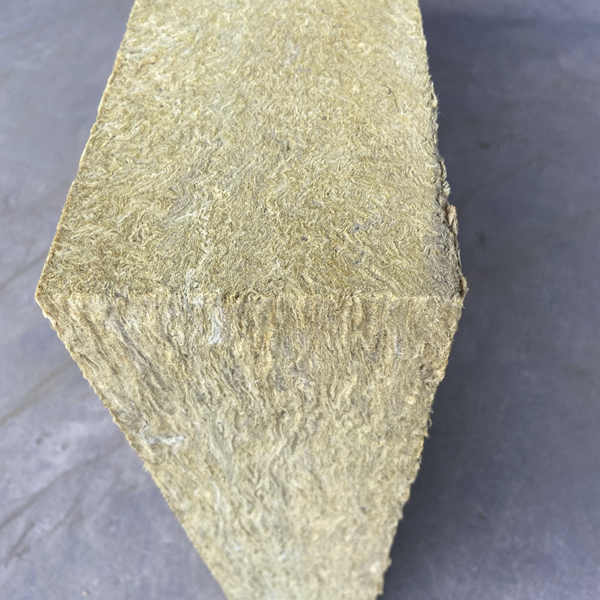

Thickness: 50mm, 75mm, 100mm

Density: 40kg/m3

Width: 400mm, 600mm

Length: 1200mm

Package: ISOKING Vacuum Export Standard

Leadtime: Around 7-10 days after advance payment

In the petrochemical field, rock wool boards have become an important material to ensure the efficient operation and safety of equipment.

When applied to petrochemical equipment insulation, the efficient thermal insulation performance of rock wool board is particularly outstanding. It can greatly reduce the heat exchange between the inside of the equipment and the outside environment, whether it is a high-temperature reactor or a tank that requires low-temperature storage, can be maintained at an ideal temperature through the rock wool board. This not only helps to improve the stability and efficiency of the production process, but also effectively reduce energy loss.

The petrochemical industry has a certain risk of fire, and the excellent fire resistance of rock wool panels gives an important guarantee. Its flame retardant properties can effectively prevent the spread of fire in the event of a fire, for emergency response to buy valuable time to protect the equipment, as well as the surrounding facilities and personnel safety.

As the petrochemical equipment is located in a complex and changing environment, rock wool board good corrosion resistance so that it can adapt to a variety of harsh conditions. Whether it is the erosion of chemicals or humidity, temperature changes, rock wool board can maintain its excellent thermal insulation and other properties do not decay.

In terms of durability, rock wool board also shows strong advantages. It is able to withstand vibration, pressure and other influences generated during the operation of petrochemical equipment for a long period of time, ensuring continuous and reliable thermal insulation.

In the installation process, rock wool board can be easily according to the shape and size of the equipment for cutting and installation, close to the surface of the equipment, forming a complete and effective insulation layer. And its construction is relatively simple and fast, will not cause too much interference to the normal operation of the equipment.

In addition, rock wool board also has a certain sound insulation effect, can reduce the noise generated by the operation of the equipment, improve the surrounding working environment. In short, rock wool board in the petrochemical equipment insulation plays an irreplaceable role, it is for the petrochemical industry's safe production and efficient operation of the credit, is to protect the stable development of the industry is one of the key materials.