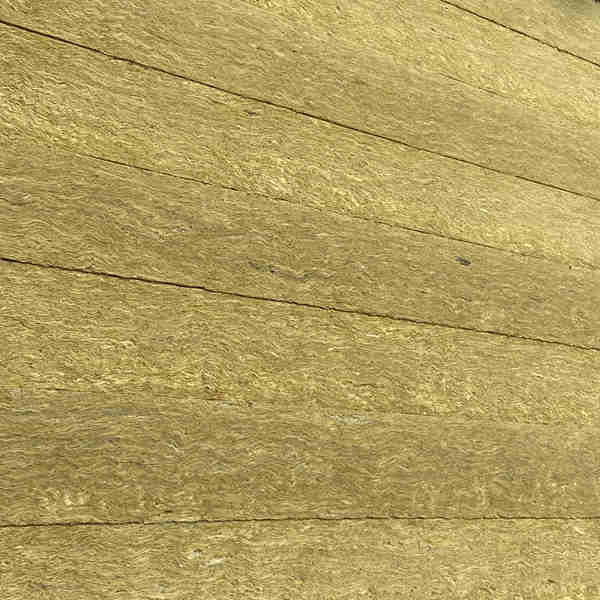

Thickness: 100mm

Density: 80kg/m3, 100kg/m3, 128kg/m3, 150kg/m3

Width: 0.6m, 1.2m...

Length: 1.2m, 2.4m...

Leadtime: Around 7-10 days after advance payment

Payment term: TT 40% in advance after contract, the balance payment paid before delivery from factory.

Specification:

Thickness: 100mm

Density: 80kg/m3, 100kg/m3, 128kg/m3, 150kg/m3

Width: 0.6m, 1.2m...

Length: 1.2m, 2.4m...

The installation process of rock wool board with foil generally includes the following steps:

Surface treatment: before the installation of rock wool board sticking foil, it is necessary to treat the surface of the grass-roots level, so that it is flat, clean, dry, and free of obvious oil, loose material and dust;

Measurement and positioning: in accordance with the requirements of the design drawings, the rock wool board sticker foil installation location for measurement and positioning, to determine the size and number of panels;

Cutting and installation: cut the rock wool board sticker foil according to the size requirements, and then place the board on the grass-roots level, and use wire and other appliances for fixing and installation;

Sealing treatment: in the joints of the rock wool board sticker foil, need to be sealed, you can use special sealant to fill, to ensure that the joints between the plates will not appear leakage, water leakage and other phenomena;

Decorative treatment: the surface of the rock wool board sticker foil can be decorated, such as painting, laying tiles, decorative panels and so on.

In the construction process, the following matters need to be noted:

Safe construction: in the installation process of rock wool board sticker foil, need to pay attention to the safety of construction, wear a good safety protection products, to avoid accidental injury;

Reasonable matching: the installation of rock wool board sticker foil should be based on the actual situation and design requirements, reasonable matching with other construction materials and equipment, to ensure the construction quality and effect;

Fire prevention measures: in the installation process of rock wool board sticking foil need to pay attention to fire prevention measures, avoid the use of open flame, in strict accordance with the fire regulations for construction;

Quality inspection: in the installation process of rock wool board sticker foil, need to inspect the quality of the board, to ensure that the board is not damaged, rupture, deformation and other defects;

Maintenance: After completing the installation of rock wool board sticker foil, need to carry out maintenance, timely cleaning, repair, replacement of damaged panels, in order to extend the service life.