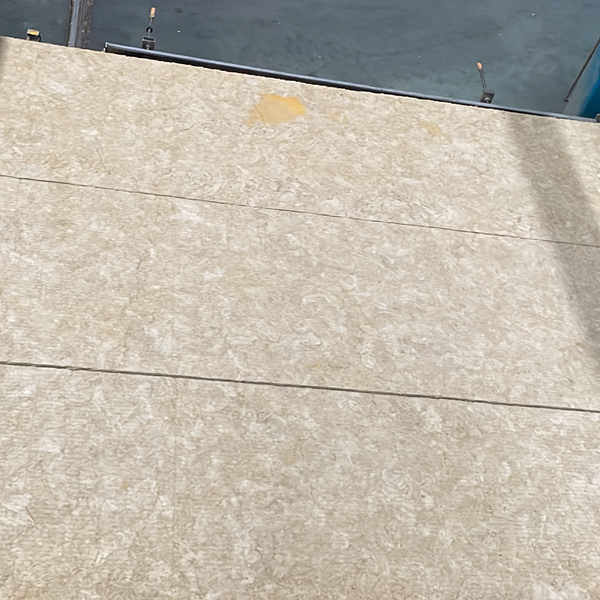

Width: 600mm

Length: 3m, 5m

Thickness: 50mm

Density: 80kg/m3, 100kg/m3

Facing: No, Plain Roll

Package: ISOKING Rock Wool Package

In the busy production of a steel plant, the hot air ducts of the blast furnace carry the heavy responsibility of transporting the high temperature hot air, and the rock wool rolls become an important role in guaranteeing the efficient operation of this key link.

The high-temperature hot air generated in the blast furnace needs to be stably transported to various working areas through the pipeline in order to maintain the normal production of the blast furnace. However, the loss of heat during this process is a problem that cannot be ignored. The application of rock wool rolls effectively solves this problem.

Rock wool rolls are made of high-quality rock wool fibers, whose unique structure and material give it excellent heat insulation performance. When the rock wool rolls are tightly wrapped around the outside of the blast furnace hot air pipeline, it is like putting a layer of highly efficient thermal insulation protective clothing on the pipeline.

In the transmission process of high temperature hot air, rock wool rolls can effectively block the heat loss to the outside world. Its internal intricate fiber structure forms countless tiny insulating spaces, greatly reducing heat conduction. Even if the ambient temperature outside the pipe is low, the high-temperature hot air inside is still able to maintain a high temperature, thus reducing the waste of energy.

This good thermal insulation brings a number of significant advantages to blast furnace production. First, it improves the efficiency of hot air utilization. Maintaining a high hot air temperature helps to improve the smelting effect of the blast furnace, speed up the production process, and improve the output and quality of steel. Secondly, reduced heat dissipation means lower energy demand, saving companies a lot of production costs.

In addition, rock wool rolls have good high-temperature resistance and are able to withstand the high-temperature environment within the hot-air ducts of blast furnaces without deformation or damage. Its durability and reliability make it able to play a long-term and stable role in insulation, reducing the frequency of maintenance and replacement, reducing the downtime of the equipment, and guaranteeing the continuity of production.

In the actual installation process, rock wool rolls are easy to construct and install, and can be flexibly cut and wrapped according to the shape and size of the pipeline to ensure a close fit with the pipeline surface, leaving no insulation dead space.

In short, rock wool rolls play a vital role in the insulation of blast furnace hot air pipes. It not only improves the efficiency of energy utilization and reduces the production cost, but also provides a strong support for the stable production and sustainable development of the steel plant.